4D Air fiber cushion production line, 2000mm ventilation air fiber elastic mattress production machine

Production line introduction:

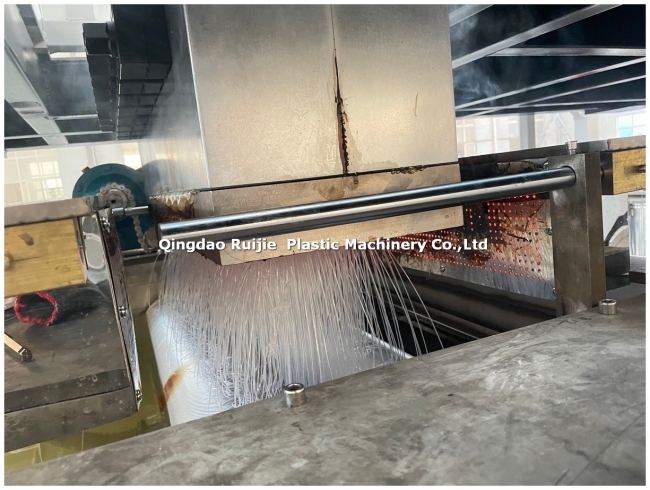

This production line uses a high-quality single-screw extruder as the main machine, adopts a PLC control system, is equipped with a hydraulic automatic screen changing system, a right-angle spinneret die, is cooled by the water tank, and is assembled with a chiller. The traction production speed is 0.2-1m/min. The cutting machine is equipped with a cooling fan to ensure that the product will not be deformed due to the high cutting temperature.

Machine list:

|

No. |

Item name |

qty(set) |

|

1 |

Mixer |

1 |

|

2 |

Automatic feeding machine |

1 |

|

3 |

Single screw extruder |

1 |

|

4 |

Spraying mold |

1 |

|

5 |

Water tank forming machine |

1 |

|

6 |

Cooling bracket and hauler |

1 |

|

7 |

Cooling cutter |

1 |

|

8 |

Stacker |

1 |

Advantages of TPE material:

(1) Non-toxic, no metal elements, no vulcanization during processing, no irritating taste.

(2) Natural oxidation and pyrolysis, scrap materials can be recycled, reducing production costs, saving resources, and avoiding environmental pollution.

(3) Lightweight, low density, easy to carry and transport;

(4) TPE material has good resilience, particularly strong support, good softness, and cushioning protection. It is used to replace sponge, spring, latex, etc. in traditional mattresses.

(5)The TPE mesh structure makes the mattress completely transparent from top to bottom, with unparalleled ventilation function, permanent ventilation and drying. The TPE material is completely washable to ensure the cleanliness of the mattress and prevent mites and bacteria from living.