SPC Flooring Production Line

SPC Flooring Production Line

Process Flow

Process: 1 mixture

According to the ratio of raw materials for automatic weighing, high-speed mixer hot mix (thermal mixing temperature: 125 ℃, role is the mixing of various materials, eliminate the moisture in the material) --enter cold mix (material cool down To prevent caking and discoloration, cold mix temperature: 55 ℃) by cooling mixing of materials;

Process 2: extrusion

Join the twin screw extruder, heated extrusion-- into the sheet forming, extruder--mould--four or five roll calender. After four or five roll calender, base material to decide to stick colorful film and stick wear-resisting layer--cooling --cutting--auto-stacker.

Process 3: UV tempering

Surface UV – tempered, tempering hot water temperature: 80 ~ 120 ℃;The cold water temperature: 10 ℃)

Step 4: slitting, slotting + packaging

Cutting, notching, trimming, chamfering to inspection, packaging

Extrusion machine list

|

No |

Parts of production line |

Description |

|

1 |

SJSZ series Conical twin screw extruder or SJSP seires Parallel twin screw extruder |

SIEMENS contactor, frequency converter,

|

|

2 |

Mould(T-Die) |

Width:1050mm |

|

3 |

Calender |

4 roller or 5 rollers |

|

4 |

Cooling bracket |

Length:6000mm or 9000mm |

|

5 |

Haul-off |

Cylinder clamping and loosening one couples |

|

6 |

Cutter |

Across cutting Lengthwise cutting |

|

7 |

Auto-stacker |

Save labor |

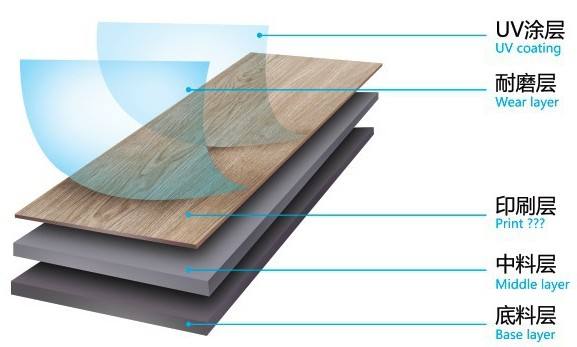

PVC lock floor/SPC Floor is made of high polymer materials, shaped by the processing of extruding, dimension stability, resists expansion and contraction, it can be installed for a fraction of the cost of ceramic, stone or hardwood flooring.

General Description

1. Use raw materials : PVC ,Caco3 plus accessories

2. Final product: L=970㎜, δ=3-8㎜

3. Production line speed : 0-6m / min

4. Capacity: 700-800kg / h

5. Total installed power : 220kw

6. Power supply : AC380V ± 10%, 50HZ

7. Working temperature: 0-40 ° C

Raw Material

PVC powder, CaCO3 and additives SPC flooring Physical performance is stable and reliable, Chemical indicators meet international standards.

SPC Flooring Feature

1, safety and environmental protection

2, waterproof and skid resistance

3, wear-resisting and fire resistance

4, weather resistance, corrosion resistance

5, luxury and beauty

6, installation convenience

Application

SPC floor can be widely used in residential bedroom, hall, kitchen and toilet ground, office buildings, libraries, museums, shopping, restaurants, factories, schools, hospitals, etc.