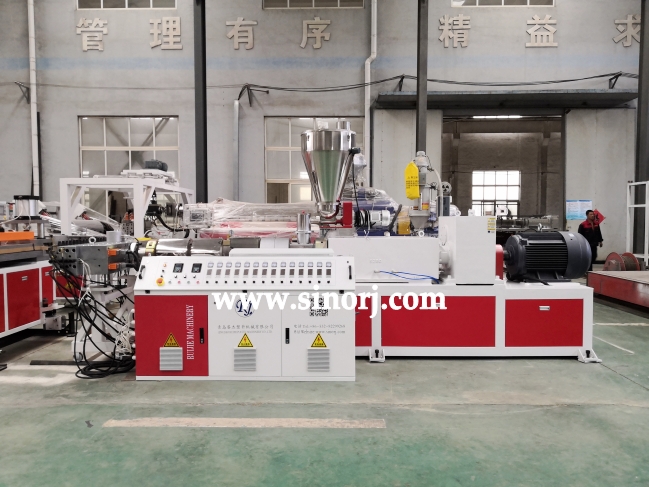

WPC Flooring Production Line

WPC Flooring Production Line

Brief introduction

This kind of machine can produce WPC floor base material board, advertising board, crust foam board, etc.

Machine include

1)SJSZ 80/156 Conical twin screw extruder

2)Hanger Mould

3)Calibartion Platform

4)Cooling Bracket

5)Haul Off Device

6)Cutting Device

7)Stacker with compact structure and superior performance

Product Advantages

1.It is very simple and convenient to operate;

2.The production line has high production efficiency;

3.Good operating system;

4.Work does not produce a lot of noise;

5.Good durability.

Finished product

WPC flooring is a new type of environmentally-friendly wood-plastic composite material. The wood phenol produced in the process of producing medium and high-density fiberboard is added to the recycled plastic to make wood-plastic composite material through granulation equipment, and then extruded production group. Made of wood plastic floor.

Product Advantages

1.It is very simple and convenient to operate;

2.The production line has high production efficiency;

3.Good operating system;

4.Work does not produce a lot of noise;

5.Good durability.

Product Advantages

(1) Waterproof and moisture proof. It fundamentally solves the problem that wood products are prone to rot after damp and moisture in humid and watery environments.The problem of expansion deformation can be used in an environment where conventional wood products cannot be applied.

(2) Insect and termite prevention, effectively eliminate insect harassment and prolong service life.

(3) Colorful, there are many colors to choose from. It has both natural wood and wood texture, and can be customized according to your own personality.

(4) It has strong plasticity and can realize individualized style very simply, fully reflecting the individual style.

(5) High environmental protection, no pollution, no pollution, and can be recycled. The product does not contain benzene, the formaldehyde content is 0.2, lower than the EO standard, and it is the European environmental protection standard. The recycling can greatly reduce the amount of wood used, and it is suitable for the national policy of sustainable development and benefit the society.

(6) High fire resistance. It can be effectively flame retardant, the fire level reaches B1 level, it will self-extinguish in case of fire, and it will not produce any toxic gas.

(7) Good processability, can be ordered, planed, sawn, drillable, and painted on the surface.

(8) Simple installation, convenient construction, no complicated construction process, saving installation time and cost.

(9) No cracking, no expansion, no deformation, no maintenance and maintenance, easy to clean, saving post-maintenance and maintenance costs.

(10) The sound absorption effect is good, the energy saving is good, and the indoor energy saving is as high as 30% or more.